CALL US

The DDG Windows Story

40 Years of Service Across East London and Essex

DDG Windows, which was originally called Discount Construction Double Glazing Ltd, was established in 1983 by four founders named Hirji, Lalji, Karsan, and Shivji. Their vision was to provide reasonably priced double glazing to the Dagenham and East London areas while supporting their families, employing local people, and delivering best-in-class service. The company quickly gained a reputation for trust, reliability, and hard work and became known as East London’s double-glazing specialists.

Since its founding, the double-glazing industry in the UK has undergone significant growth. In the 1980s, double glazing was considered a luxury item affordable only for a small percentage of homeowners. However, as technology improved and production costs decreased, double glazing became more affordable for the average homeowner.

In the 1990s and 2000s, double glazing became increasingly popular as homeowners sought to improve their homes’ energy efficiency and reduce their heating bills. DDG was able to stay ahead of the competition thanks to its reputation for best-in-class service, top-of-the-range double-glazing products, including windows, doors, bi-folding doors, casement windows, and sky lanterns, not to mention exceptional customer service.

DDG has experienced many significant milestones since its establishment. The first factory was set up in October 1983 on Shaftesbury Road, E7, where the founders began manufacturing aluminium windows with hardwood frames. Limited space at the factory led to the purchase of 844 Romford Rd, E12, in August 1986.

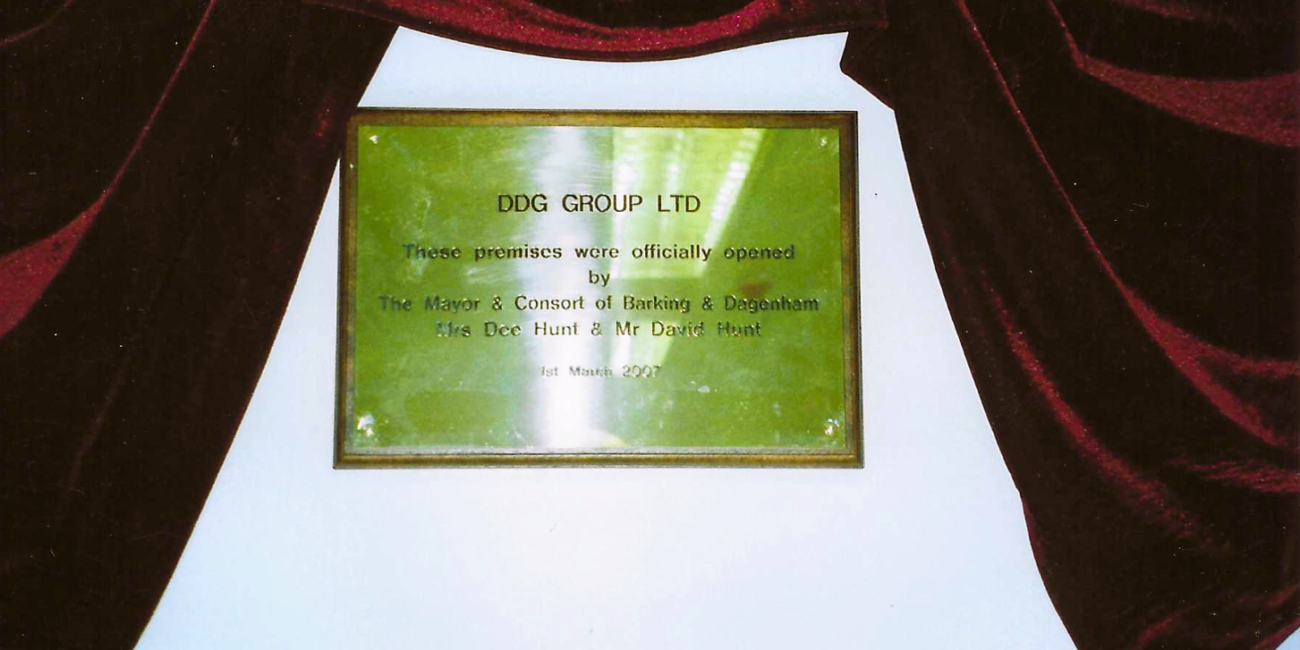

This new factory provided space to increase the product range and manufacture the latest advancement in double glazing – UPVC windows – for the first time. DDG moved to a larger premises, located in Stratford on Marshgate Lane E15 [7,000sft], in November 1997, and then in July 2006 to 101 Wantz Rd in Dagenham [30,000 sft].

DDG’s move to Dagenham allowed the company to purchase the latest technology, including the Rotox Corner Cleaner, which revolutionised the finishing process, freeing up time and perfecting quality.

Over the last 40 years, DDG has been able to help more customers with state-of-the-art engineering and faster supply chains. The company has invested in delivery vans and personnel to manufacture and finish windows and doors that customers can be proud of.

With each technological advancement, DDG has adapted to the growing needs of its customers, purchasing new equipment to improve production times and product quality.

In 2014, the Emmegi Phantomatic T3A (2014) and the Emmegi Classic Magic machines were added to the factory floor, and used to cut and shape metal (aluminum) frames and profiles for windows, doors, and curtain walls. Making the manufacturing process faster, more accurate, and less prone to errors. This lead DDG to produce better quality products, increased productivity, and ultimately, higher customer satisfaction.

Keeping up with technology, DDG invested again in 2021 with the The Stuga Autoflow, a sawing and machining center. Performing a variety of cutting, drilling, and milling operations on uPVC profiles to create the necessary components for the assembly of window and door frames. The machine is highly automated, allowing for precision cutting and machining of materials in large quantities and at high speeds. Giving customers a better quality product in a shorter time frame.

In their 40th year, DDG’s birthday present to benefit customers is on the factory floor: The Haffner AL220/80 aluminium cutting & prep centre. By providing precision cutting and preparation of aluminium materials. This results in more accurate and efficient production of aluminium windows, doors, and frames, which leads to higher quality finished products for customers. Additionally, the use of this machine can increase the speed and efficiency of production, allowing for faster turnaround times and potentially lower costs for customers.

DDG has faced several challenges over the years, such as economic downturns and natural disasters. However, the company has always been able to overcome these obstacles thanks to its hard-working employees and strong core values. DDG has also made significant contributions to the local community, such as sponsoring events and contributing to charitable causes.

The future looks bright for DDG as the company plans to continue growing and adapting to changes in the industry. DDG’s focus on innovation, quality, and customer service will undoubtedly lead to many more years of success.

Before we wrap up, we want to extend our thanks to all those people and suppliers who have supported us over the past 40 years. It’s no small feat to have thrived for four decades in such a dynamic industry, however our commitment to excellence and innovation in the field, along with your unwavering support give us the motivation to carry on. Here’s to another 40 years of success!

Be part of our story - fill the form to get in touch with us!

Need to discuss windows and doors options for your home?

Call us anytime on 0208 514 0819

40 YEARS OF

PROUDLY SERVING

LONDON

& ESSEX

WE HAVE AMAZING LEVELS

OF CUSTOMER

SATISFACTION

WE ONLY USE

QUALITY MATERIALS

FOR YOUR HOME